- HOME

- Products

- Basic materials

- Technical conditions

- Technological equipment

- CAD CAM

- The Laser Photoplotter

- CNC drilling and routing

- UV Laser drilling and routing

- Laser Tannlin TX PROi

- Direct plating

- Vyplňování otvorů | Planarizer

- Surface readjustments

- Surface finishes

- Galvanic processes

- Digital Direct Imaging

- The etching

- Solder mask and silkscreen

- Inspections of PCB

- Controlled impedance

- Multilayer lamination

- Contour fabrication

- Analytical Laboratory

- PCB Designs

- PCB assembly

- Terms and Conditions

- Preislist

- Contact

- kariéra

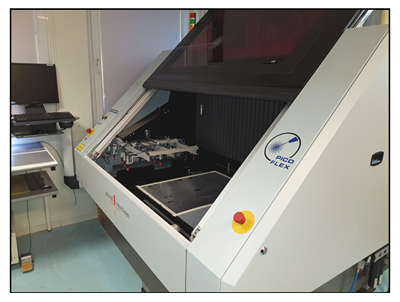

Pico Flex + Laser Flex : laser drilling and routing

Rapidly evolving laser source technologies are also enabling PCB manufacturing to achieve new levels of quality required by current design trends. The transition from lasers with pulse lengths in nanoseconds to picosecond lasers represents a major breakthrough in the processing of all materials. The pulse energy of a picosecond laser is so high that cold abrasion of materials occurs, without heat affecting the surrounding beam.

The acquired laser drill brings the possibilities of drilling much more precise blind hole shapes in any material being processed. Cutting flexible materials without edge carbonization takes Flex and Flex-Rigid plate production into a new, otherwise unattainable realm of quality. The machine's software is perfectly adapted to the production of printed circuit boards. As usual, the base of the machine consists of a solid granite bed, which ensures the machine's consistent accuracy in the micrometer range. Equipping the machine with an automatic stacker enables unattended operation for the production of larger series of HDI boards.

| Working table | 558 x 700mm |

| Speed of positioning | 120m/min |

| Accuracy of positioning | +/- 0,007mm |

| position repeatability | +/- 0,002mm |

| UV laser system | SLD50 |

| Wavelength | 532nm |

| Pulse frequency | 200-1000kHz |

| Data format | DXF, Excellon |

| Clamping | Vacuum table |

New technology of UV laser drilling and milling was installed in PragoBoard at the end of March. Highly efficient and accurate system for MICROVIA and blind holes, a dynamic linear motors and precision optics guarantees excellent quality of drilled holes and milled edges. The device can also be used for milling of flexible printed circuits, coverlay masks and other basic materials for their production. There is no need to clamp material into the machine board. Its exact position is secured by the vacuum table and the camera system. The UV laser cutter will refine on and improve production of FLEX-RIGID boards, where classical routing technology was not sufficient. With this technology final shape milling will be also improved for any flexible parts and basic material will be saved (due to minimal rebounds of motifs among themselves) and thought the total price for the PCB will be better.

New technology of UV laser drilling and milling was installed in PragoBoard at the end of March. Highly efficient and accurate system for MICROVIA and blind holes, a dynamic linear motors and precision optics guarantees excellent quality of drilled holes and milled edges. The device can also be used for milling of flexible printed circuits, coverlay masks and other basic materials for their production. There is no need to clamp material into the machine board. Its exact position is secured by the vacuum table and the camera system. The UV laser cutter will refine on and improve production of FLEX-RIGID boards, where classical routing technology was not sufficient. With this technology final shape milling will be also improved for any flexible parts and basic material will be saved (due to minimal rebounds of motifs among themselves) and thought the total price for the PCB will be better.

|

|

|

| Working table | 600 x 650mm |

| Speed of positioning | 100m/min |

| Accuracy of positioning | 0,005mm |

| UV laser system | DPSS Q304 11W |

| Wavelength | 355nm |

| Pulse frequency | 0 - 250kHz |

| Sighting marks | min. 4x ( round or cross ) |

| Marks diameter | 0,5 - 1,0mm |

| Data format | DXF, Gerber, Bitmapa |

| Clamping | Vacuum table |

company adress :

company adress : place of business :

place of business :